Kardex Shuttle

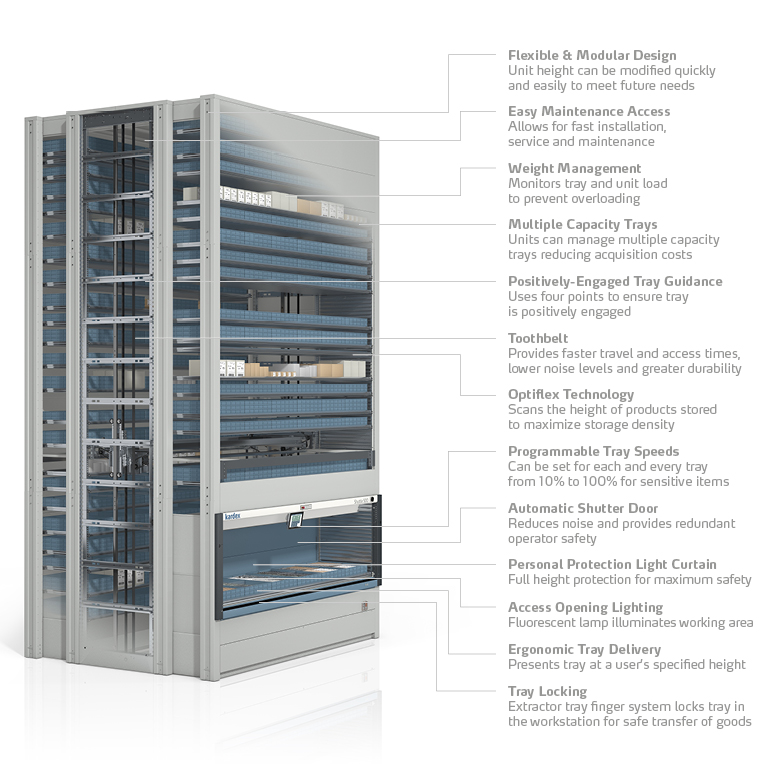

Maximize your storage capacity and streamline operations with the Kardex Shuttle. This advanced automated storage and retrieval system uses a modular, vertical design to make the most of your floor space while keeping parts and materials secure, organized, and instantly accessible.

How a Modular VLM works

How a Modular VLM works